what is the purpose of brinell hardness test|brinell hardness explained : manufacturing The Brinell hardness test method as used to determine Brinell hardness, is defined in ASTM E10. Most commonly it is used to test materials that have a structure that is too coarse or that have a surface that is too rough to be tested . webFale conosco! Encaminhe suas dúvidas, críticas, sugestões, elogios ou queixas. O Spartanas Acompanhantes fica à sua disposição para auxiliar seja qual for o seu .

{plog:ftitle_list}

Resultado da Go to https://www.replaypoker.com, then click Log in to Replay Poker, or .

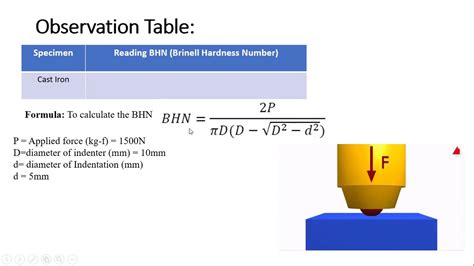

In the manufacturing industry, we are measuring the hardness of the metal by various hardness tests and one of them is the Brinell Hardness Test. In this article, we will see its performing methods, advantages, .The Brinell hardness test is a widely recognized method for determining the hardness of various materials. It involves applying a constant load or force, typically ranging from 187.5 to .The Brinell hardness test method as used to determine Brinell hardness, is defined in ASTM E10. Most commonly it is used to test materials that have a structure that is too coarse or that have a surface that is too rough to be tested . Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. It is used in a number of industries for material comparison and selection, as well .

As per the name, the Brinell hardness test is used to determine the hardness of the given material and this hardness test is in use for many years. As per its definition, a small metal ball acts as the indenter and a force is applied on the .

The Brinell hardness number (HB) is the load divided by the surface area of the indentation. The diameter of the impression is measured with a microscope with a superimposed scale. The Brinell Hardness Number HB .Brinell was a Swedish engineer who developed this testing process to determine both hardness and tensile strength. It consists of indenting the surface of the metal by a hardened steel ball .Brinell hardness is a unit of measurement that indicates the hardness of a material. It is measured using the Brinell hardness method, for which a hardmetal ball is pressed into the material. The size of the resulting indentation is .The Brinell method can be used for testing non-homogeneous materials (e.g. castings), because the large ball comes into contact with many crystals (different metallographic .

History Behind the Brinell Test. Let’s take a quick glance at the history behind the Brinell test. In 1900, Dr. J.A. Brinell invented this test. As an honor to him, the test named as a Brinell test. It is the oldest hardness test of all time. .The Brinell hardness test method as used to determine Brinell hardness, is defined in ASTM E10. Most commonly it is used to test materials that have a structure that is too coarse or that have a surface that is too rough to be tested .Though loads of 500, 1000, 1500, 2000, 2500, and 3000 N are available in a typical Brinell hardness tester, a load of 500 N is used for testing relatively soft metals such as copper and aluminium alloys, while the 3000 N load is often used for testing harder materials such as steels and cast irons.However, the general rule is that the combination of test load and ball diameter .The Brinell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical characteristics of metallic materials, and may be useful in quality control and selection of materials. .

termite detection moisture meter

1.5 At the time the Brinell hardness test was developed, the force levels were specified in units of kilograms-force (kgf). Although this standard specifies the unit of force in the International System of Units (SI) as the Newton (N), because of the historical precedent and continued common usage of kgf units, force values in kgf units are provided for information . The Brinell hardness test is not suitable for very hard materials or hardened surface layers because the ball does not penetrate sufficiently into the material. Higher test loads are not the solution at this point, as this leads to deformation of the carbide ball. The flattening of the ball results in a larger indentation diameter and thus .The Brinell method has the following advantages: The Brinell method can be used for testing non-homogeneous materials (e.g. castings), because the large ball comes into contact with many crystals (different metallographic constituents of the material), thereby forming a .

A full range of consumables for hot and cold mounting with different hardnesses for conductive and general-purpose use, including clear, transparent, fast-curing and no-shrinkage mounts. . As the Brinell hardness test (HBW) indentation leaves a relatively large impression, the Brinell hardness test is better suited to larger samples with a . In a Brinell test, the estimation of hardness takes place through the process known as indentation. It consists of applying an object (indenter or penetrator) with a certain load on the surface of the material to be studied. . The storage or technical access is strictly necessary for the legitimate purpose of enabling the use of a specific . The Brinell hardness test is ideal for measuring the hardness of metals with coarse or inhomogeneous grain structures, such as cast iron and softer metals like aluminum alloys. It measures the diameter of a larger indentation, which averages out variations in the material’s microstructure, providing a more representative hardness value for .

Brinell Hardness Testing: Involves applying a known load to the surface of the test sample via a hardened steel or carbide ball; Vickers Hardness Testing: . The purpose of hardness testing is to measure the colour, transparency, and luminance of materials, important for industries like interior design and ceramics. .

Hardness testing methods: Rockwell, Brinell and microhardness Heat treating has evolved into a highly complex, precise process that improves characteristics of metal parts. A critical component of quality heat treating is employing the correct hardness testing method to show manufacturers their parts achieve design requirements.Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load).Brinell Hardness Test: Using a spherical indenter, this test determines the hardness by measuring the diameter of the indentation created by a known force. It’s suitable for materials with coarse grain structures or rough surfaces.The Brinell hardness test is used to measure and inspect materials with rough surfaces such as forgings and casting because you cannot use other methods to inspect them. This is because this method uses a large indenter (usually 10 mm) which averages the rough surface of the test piece for better results. It is also used to assess the hardness .

The test provides numerical results to quantify the hardness of a material, which is expressed by the Brinell hardness number – HB. The Brinell hardness number is designated by the most commonly used test standards (ASTM E10 .Brinell Hardness Test. The oldest of the hardness test methods in common use on engineering materials today is the Brinell hardness test. Dr. J. A. Brinell invented this test in Sweden in 1900. The Brinell test uses a desktop machine to apply a specified load to a hardened sphere of a specified diameter. The Brinell hardness number, or simply .See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload .

how to calculate brinell hardness

brinell hardness testing machine diagram

Other articles where Brinell hardness test is discussed: Johan August Brinell: .Swedish metallurgist who devised the Brinell hardness test, a rapid, nondestructive means of determining the hardness of metals.Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and . Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. . Selection Table of Brinell Hardness Test P/D 2. Material type: Brinell hardness number/HB: Sample thickness/mm: Relationship between load P and indenter diameter D: Diameter of indenter D/nm: Load P/kgf: Load .

Purpose Compatible Materials; . The Brinell hardness test is named after its inventor, Johan August Brinell. It involves applying a constant load or force to a spherical indenter made of hardened steel or carbide onto the surface of the material being tested. The indentation diameter is then measured optically.An alternative method is the Brinell hardness test, which uses a hardened steel (or tungsten carbide) ball indenter with a diameter D of, usually, 10 mm.This is applied under a load P of 500–3000 kg applied for 10–30 s.The diameter of the circular indentation d is measured in millimetres. The hardness number, (HB) is calculated using the following equation:

General-purpose polystyrene is clear, hard, and rather brittle. It is a colorless and transparent thermoplastic. . Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. The Brinell hardness testing uses a 10mm hardened steel ball, while the Rockwell test uses either a much smaller steel ball (<4mm) or a diamond cone, depending on the material being tested. The Rockwell test measure the depth of the indentation, while the Brinell test measures the width of the indentation. Rockwell hardness tests use a preload .

The Brinell hardness test is an optical testing method for samples with coarse or inhomogeneous grain structure. This is the best test method for achieving the bulk or macro-hardness of a material, particularly those materials with heterogeneous structures.Hardness Numbers – Brinell. Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be .

termite inspection moisture meter

É um portal que permite que você negocie seus débitos O Boticário de forma simples, rápida e segura, na hora e no lugar mais apropriado para você. Caso o seu Espaço do Revendedor O Boticário não tenha disponibilizado o Portal para Negociação, seus débitos não estarão disponíveis para consulta. Nesse caso, contatar o (a) seu (sua .

what is the purpose of brinell hardness test|brinell hardness explained